20 Layer PCB

20 Layer Panasonic M6 6Steps HDI High Speed PCB printed circuit boards

Specification

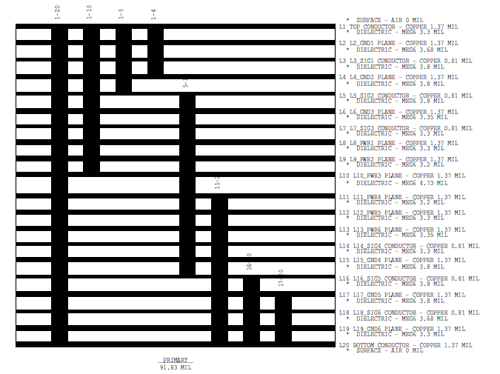

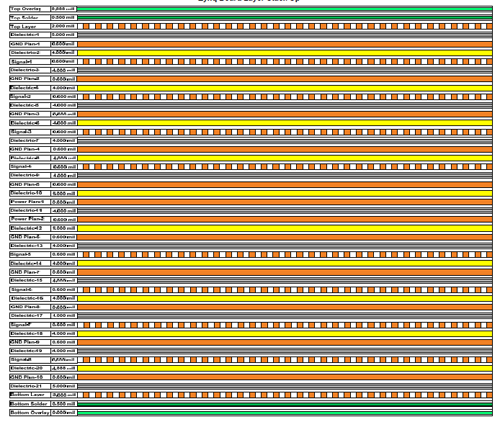

Stack up:

What are the main difficulties in the production of high-level multilayer PCB circuit boards?

First, the main production difficulties

Compared with the characteristics of conventional circuit boards, high-level circuit boards have the characteristics of thicker plates, more layers, denser lines and vias, larger cell sizes, thinner dielectric layers, etc., inner space, interlayer alignment, Impedance control and reliability requirements are more stringent.

1.1 Difficulties in alignment between layers

Due to the high number of high-layer slabs, the customer design end is more and more strict on the alignment of the PCB layers. Generally, the inter-layer alignment tolerance is controlled by ±75μm. Considering the high-level board unit size design, the graphic transfer workshop environment temperature and humidity, As well as the misalignment and interlayer positioning methods caused by the inconsistency of different core layers, the interlayer alignment control of the high-rise boards is more difficult.

1.2 Difficulties in the production of inner layers

The high-rise board adopts special materials such as high TG, high speed, high frequency, thick copper and thin dielectric layer, which puts high requirements on the inner layer circuit production and graphic size control, such as the integrity of impedance signal transmission, which increases the difficulty of inner layer circuit fabrication. The line width is small, the open circuit is increased, the short is increased, the pass rate is low; the signal line of the fine line is more, the probability of the AOI leak detection is increased; the thickness of the inner core plate is thin, and the fold is easy to cause poor exposure, etching It is easy to roll when passing the machine; most of the high-rise boards are system boards, the unit size is large, and the cost of scrapping the finished product is relatively high.

1.3 Pressing and manufacturing difficulties

A plurality of inner core sheets and prepregs are stacked, and defects such as sliding sheets, delamination, resin voids, and bubble residues are easily generated during press production. When designing the laminated structure, it is necessary to fully consider the heat resistance, withstand voltage, the amount of glue and the thickness of the material, and set a reasonable high-level plate pressing program. The number of layers is large, the amount of expansion and contraction control and the compensation of the size factor cannot be consistent; the interlayer insulation layer is thin, which easily leads to the failure of the interlayer reliability test. Figure 1 is a defect diagram of the blasting delamination after the thermal stress test.

1.4 Difficulties in drilling

The use of high TG, high speed, high frequency, thick copper special plates increases the difficulty of drilling roughness, drilling burrs and drilling. The number of layers is large, the total copper thickness and plate thickness are accumulated, the drill is easy to break the knife; the dense BGA is more, the CAF failure problem caused by the narrow hole wall spacing; the plate thickness is easy to cause the oblique drilling problem.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy