Products

The Critical Role of FR-4 in High-Tg PCB Design and Applications

- Special Shape PCB

- fr4 PCB

- High TG PCB

- HDI PCB

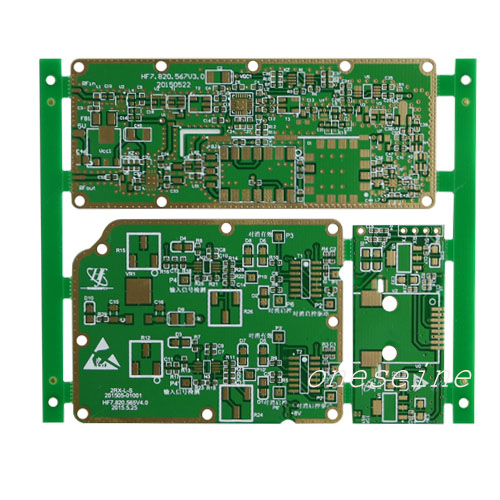

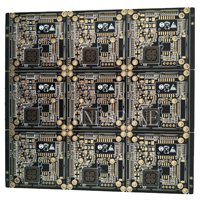

- Product description: FR-4 Tg170 thermal reliability high power PCBs automotive high tg pcb manufacturer for ECU cost effective high tg pcb material benefits of high tg fr4 for lead-free assembly quick turn high tg pcb

The Critical Role of FR-4 in High-Tg PCB Design and Applications

PCB Specification:

Brand:ONESEINE

PCB size:11*13CM

Surface finish:ENIG

Solder mask:Green

Copper:1OZ

The Critical Role of FR-4 in High-Tg PCB Design and Applications

Is your next-generation electronic device pushing the limits of power and speed? As operating frequencies soar and power densities increase, managing heat becomes the single greatest challenge to reliability. For countless designers confronting this reality, one material continues to provide the foundational solution: FR-4 with a High Glass Transition Temperature (High Tg).

While exotic, high-cost materials often steal the spotlight, the evolution of standard FR-4 into High-Tg formulations makes it the unsung hero of high-performance printed circuit boards (PCBs). Let's explore why.

The Heat Challenge: Why Standard FR-4 Isn't Always Enough

Every PCB substrate has a Glass Transition Temperature (Tg)—the point at which the material changes from a rigid, glassy state to a soft, rubbery one. Standard FR-4 (Tg ~130-140°C) is sufficient for many consumer applications. However, in demanding environments, excessive heat can cause:

Delamination: Layers of the PCB separate.

Copper Barrel Cracking: Failure of plated through-holes.

Reduced Electrical Integrity: Loss of insulation resistance and signal integrity.

Enter High-Tg FR-4, a material engineered with a Tg typically exceeding 170°C. This isn't a minor upgrade; it's a fundamental leap in thermal resilience that is critical for modern electronics.

Why High-Tg FR-4 is the Go-To Material for Demanding Applications

The "critical role" of High-Tg FR-4 is defined by a powerful combination of performance, reliability, and cost-effectiveness.

1. Unmatched Thermal Endurance:

High-Tg FR-4 maintains its mechanical and dimensional stability at elevated temperatures encountered during both manufacturing (like multiple lead-free soldering cycles) and operation (in hot environments like under a car hood or inside a server rack). This directly translates to long-term reliability and a lower failure rate.

2. Enhanced Mechanical Stability:

At high temperatures, High-Tg FR-4 offers superior resistance to Z-axis expansion. This is crucial for protecting the integrity of plated through-holes, especially in thick, multi-layer boards, preventing costly intermittent connections or catastrophic failures.

3. Superior Moisture Resistance:

High-Tg formulations inherently offer better resistance to moisture absorption. This is vital for applications that face humid conditions or large thermal cycles, as moisture can lead to conductive filament formation (CAF) and electrical shorts.

4. The Critical Cost-Performance Balance:

This is where High-Tg FR-4 truly shines. While materials like polyimide or PTFE may offer higher performance in specific niches, they come at a significantly higher cost. High-Tg FR-4 delivers ~80-90% of the performance for often less than half the price, making it the most rational and economical choice for a vast majority of high-performance applications.

Key Applications Where High-Tg FR-4 is Indispensable

You'll find High-Tg FR-4 at the heart of the technologies that drive our world forward:

Automotive Electronics: Engine Control Units (ECUs), LED lighting, power converters, and ADAS systems that must withstand under-hood temperatures.

Industrial Power Electronics: Motor drives, power supplies, and control systems where high currents generate significant heat.

Telecommunications & Computing: Network switches, routers, servers, and base station hardware that run 24/7 at high processing loads.

Medical Electronics: Critical diagnostic and imaging equipment where absolute reliability is non-negotiable.

Aerospace & Defense Systems: Avionics and navigation systems that face extreme environmental stress.

Partner with a Manufacturer Who Understands the Critical Details

Specifying High-Tg FR-4 is just the first step. Realizing its full potential requires a manufacturing partner with deep expertise in processing this material. From precise lamination control to optimized drilling and desmearing, the right partner ensures your design's integrity is preserved from blueprint to final product.

Ready to leverage the critical advantages of High-Tg FR-4 for your next project? Don't let thermal challenges compromise your design's reliability.

ONESEINE TECHNOOGY specializes in high-performance PCB manufacturing. We provide expert guidance on material selection and precision fabrication to ensure your products are built to last.

Contact us today for a quick quote or to consult with our engineering team!

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy