Fr4 PCB

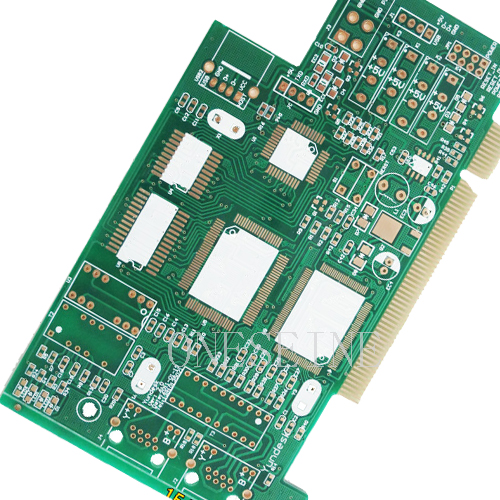

High TG Gold Finger Multilayer Fr4 PCB Printed Circuit Board Prototype

- Gold Finger

- Multilayer Fr4 PCB

- High TG

- MIn hole:0.15mm

- Product description: tg 150-160 board tg what is high tg pcb manufacturers low tg fr4 pcb td pcb assembly china

High TG Gold Finger Multilayer Fr4 PCB printed circuit board Prototype

Quick detail:

|

Material |

Min line |

3/3 |

|

|

Layer |

6 |

Min hole |

0.15mm |

|

Surface finish |

HASL lf |

Stack up file |

yes |

|

Copper |

2OZ |

Blind hole |

yes |

|

Thickness |

1.25MM |

Quantity |

prototype |

What is High Tg PCB (printed circuit board)

• In recent years, there are more and more customers request to manufacture PCB with high Tg, in the following we would like to describe what is high Tg PCB.

• TG means Glass Transition Temperature Temperatures that are associated with long term operations must be considered in the manufactured of printed circuit boards that will be exposed to high thermal loads.. The function of a circuit board will be affected if its temperature exceeds the designated Tg value. You can count on Super PCB for a high TG PCB that won’t fail you.

• Normally high Tg refers to high heat resistance in PCB raw material, the standard Tg for copper clad laminate is between 130 – 140℃, High Tg is generally greater than 170℃, and middle Tg is generally greater than 150℃. Basically the printed circuit board with Tg≥170℃, we call high Tg PCB. As the rapid development of electric industry, especially for the computer as the representative of electronic products, developing toward the high performance, high multilayer requires PCB substrate material with higher heat resistance to ensure high reliability. On the other hand, as a result of development of SMT, CMT with high density pcb assembly technology, the PCB manufacturing with small hole size, fine lines and thin thickness are more and more inseparable from the support of high heat resistance.

• If the Tg of PCB substrate is increased, the heat resistance, moisture resistance, chemical resistance and stability of printed circuit boards will be improved as well. The high Tg applicates more in the lead free pcb manufacturing process.

• Therefore, the difference between general FR4 and high Tg FR4 is, in the hot state, especially in the heat absorption with moisture, the high Tg PCB substrate will perform better than general FR4 in the aspects of mechanical strength, dimensional stability, adhesiveness, water absorption and thermal decomposition.

• High Tg refers to the high heat resistance.With the rapid development of electronic industry, especially the electronic products represented by computer, toward high function, high multiple stratification, need PCB substrate material of higher heat resistance is an important guarantee.Represented by SMT, CMT's emergence and development of high density installation technology, make the PCB in the small aperture, fine lines, thin, more and more inseparable from the support substrate, high heat resistance.

• Commonly so FR - 4 and the difference between high Tg FR - 4: is under the hot, especially in the heat after moisture absorption, its material mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion situations vary, such as high Tg products is significantly better than the ordinary PCB substrate materials.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy