Fr4 PCB

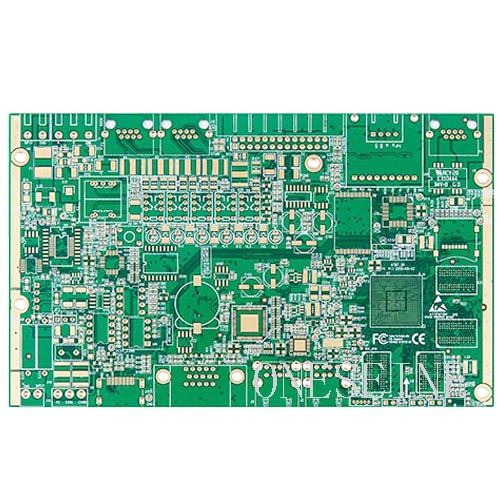

6 Layer Medical Equipment X-ray Inspection PCB Printed Circuit Board

- 6 layer

- Medical Equipment pcb

- X-ray Inspection PCB

- Printed Circuit Board

- Product description: pcb x ray inspection service automated optical inspection pcb x-ray machine PCB

6 Layer Medical Equipment X-ray Inspection PCB printed circuit board

Quick Details

Place of Origin:Guangdong, China (Mainland)

Brand Name:ONESEINE

Base Material:FR-4/HTG150-180 FR-4/CEM-1/CEM-3/Aluminum

Copper Thickness:1oz

Board Thickness:1.6mm

Min. Hole Size:0.20mm

Min. Line Width:0.254mm

Min. Line Spacing:3mil

Surface Finishing:HASL Immersion Gold OSP

Product name:6 Layer Medical Equipment X-ray Detector PCB printed circuit board

Certificate:ISO 9001:2008/ISO

Item:PCBA Electronic

Solder mask:Double-sided Green LPI

Testing Service:X-Ray

SMT Efficiency:TQFP

Shipping:DHL UPS TNT Fedex

Application:Medical Device Consumer,Telecom,Industrial,Aero Industry

PCB material:FR4

Applicaitons:

1, communication industry

2, medical equipments

3, consumer electronics

4, automobile industry

Our Advantage:

Competitive price with superior quality and stable reliability.

On-time delivery for sample, quick-turn, pilot run and large volumes.

Professional technical supports and prompt response to customers’ requests.

Logistics supports, various choice of shipping method, UPS, DHL, Fedex, sea/air cargoes.

Flexible payment choice, T/T, L/C and so on

Features:

1. With the strong support of advanced R&D Dept and equipment, your products are well guaranteed.

2. We put our customers' requirement always first, try our best to meet your demand.

3. printed circuit board prototype pcb prototypes pcb design.

High frequency telecom.high speed transmission high security.

High transmission quality.high memory transaction

Specification

Teflon PCB

Single.double Sided Teflon PCB

NPTH,PTH

Conductor width control: ±0.02mm

Hole wall copper ≥ 20μм

Thermal stress 288°C.10sec.

Permitivity ε2.1-10.0

Profile:punching or routing.tolerance ±0.10.0-0.13mm

Final product thickness 0.5,0.8,1.0,1.2,1.6mm

Base copper thickness Normal 0.5 1.0 OZ

Solder Mask Taiyo PSR4000.Tamura DSR2200

Solder mask thickness on tracks 20-30 μм

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy