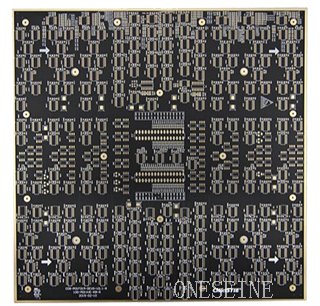

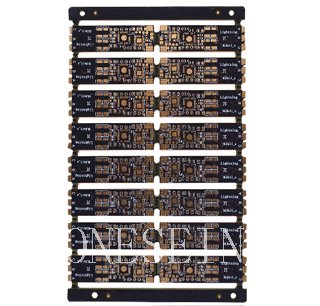

PCB Board

2Layer CEM-3 Material PCB Circuit Board

- cem-3 material

- 2 layer

- black soldermask

- pcb board

- Product description: 2Layer CEM-3 Material PCB Circuit Board

2Layer CEM-3 Material PCB Circuit Board

PCB material:CEM-3

Product name: automotive electronics pcb

Layer:2

Surface finish:ENIG

Copper weight:1OZ

Line width:6mil

Thickness:1.6mm

The difference between CEM-3 and FR-4

Double-sided and multi-layer printed circuit boards for electronic products now usually use FR-4 substrate, which is a copper-clad flame-retardant epoxy glass cloth board. CEM-3 is a new type of substrate material for printed circuit developed on the basis of FR-4. In recent years, Japan has adopted a large number of CEM-3 to replace FR-4, even exceeding the amount of FR-4. About 55% of double-sided panels use CEM-3. 1. CEM-3 is a composite copper clad laminate

FR-4 is made of copper foil and glass fiber cloth impregnated with flame retardant epoxy resin. The difference between CEM-3 and FR-4 is that it uses a composite substrate of glass cloth and glass mat, also known as composite Type substrate, not just glass cloth.

The production process of CEM-3 is similar to FR-4. The gluing of the glass mat can be vertical gluing or horizontal gluing. The epoxy resin system used is the same as FR-4. In order to improve performance, it can be modified, usually a certain amount of filler is added. The suppression pressure is generally half lower than FR-4. In order to meet the requirements of different thicknesses, glass mats of different standard weights can be used, and the commonly used ones are 50g, 75g, and 105g.

Second, CEM-3 performance

If CEM-3 wants to replace FR-4, it must achieve the various properties of FR-4. The current CEM-3 has overcome the defects of early CEM-3 products such as poor quality of punching metallization, warpage and dimensional stability by improving the resin system, glass mat, and lamination manufacturing process. CEM-3's glass transition temperature, immersion resistance, peeling strength, water absorption, electrical breakdown, insulation resistance, UL indicators, etc. can all meet the FR-4 standard, the difference is that CEM-3 has low bending strength

In FR-4, the thermal expansion is greater than FR-4.

CEM-3 metallized hole processing is not a problem, the drill bit wear rate of drilling processing is low, it is easy to punch and press forming processing, and the thickness and dimension accuracy are high, but the metalized appearance of punching is slightly worse. 3. CEM-3 market application

UL believes that CEM-3 and FR-4 are interchangeable, so the current double-sided FR-4 can generally be used as a replacement object. Because CEM-3 has similar performance to FR-4, it has become possible to substitute it on multilayer boards.

Due to the fierce price competition for printed circuit boards, the four-layer board market has also begun to consider CEM-3. But for thin plates (<0.8mm), the price advantage does not exist.

printed circuit boards made of CEM-3 are now used in fax machines, copiers, instruments, telephones, automotive electronics, household appliances and other products

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy