High Frequency PCB

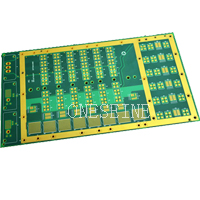

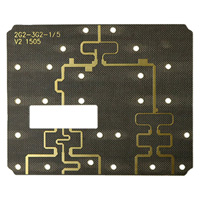

5.8GHZ / 24GHZ Antenna Sensor Module PCB Circuit Boards

- High frequency PCB

- Rogers PCB

- 5.8GHZ PCB

- Sensor PCB

- Product description: 5.8GHZ / 24GHZ Antenna Sensor Module PCB Circuit Boards

5.8GHZ / 24GHZ Antenna Sensor Module PCB Circuit Boards

Sensor PCB boards Specification:

Number of layer: 2

Board size: 2.2*2.2cm

Panel size: 30*18cm

Color: Green solder mask black silk screen

Craft edge:yes

Surface finish: Immersion gold

Material: Rogers 4350 0.254mm

Gerber file: required

Name:24GHZ Rogers K-band X-band Rigid Custom PCB Boards for Automatic Door Module

Automatic Door / Sensor Lamp Rigid PCB 2 Layer Control Board With Rogers Material Raw

Sensor PCB information:

The current civilian Doppler microwave sensors are operating in C-band (5.8GHz), X-band (10.525 / 10.687GHz) and K-band (24.125GHz), its transmit power less than 10 mW, are specified in the ITU You do not need to apply for the use of the frequency ISM band. Detection pattern omnidirectional and directional, depending on the antenna gain and transmit power, the detection range of 0.1 to 50 meters.

Microwaves emitted by the transmitting antenna, will be absorbed or reflected by the object is encountered, the power change. If the receiving antenna through the use of the object from the measured object or microwave reflected, and converts it into an electrical signal, and then processed by the measurement circuit, to achieve a microwave detection. Microwave sensors mainly by the microwave oscillator and the microwave antenna. Microwave oscillator is a device for generating microwaves. There are microwave oscillator device comprising klystron, magnetron or some solid elements. An oscillation signal generated by the microwave oscillator required waveguide transmission, and through the antenna out. In order to launch a consistent directional microwave antenna should have a special structure and shape.

PCB Sensor Specifics

At a high level, the capacitive sensor dependencies can be visualized by understanding the basics of a plate capacitor.

First the base capacitance must be accounted for. The term “base capacitance” refers to the measurement result of an “untouched” or uninfluenced sensor element. For simplicity, the base capacitor can be assumed to be constructed from the sensor pad on the topside of the PCB and the ground pour on the bottom side of the PCB.

The PCB itself makes up the “d” in the equation. As mentioned earlier, as d gets smaller (such is the case with flex PCBs), the baseline capacitance increases resulting in reduced sensitivity. The permittivity of free space (ε0) and the material (εr ) define the dielectric constant of the PCB insulator and will affect the ultimate base value. The area of the sensor, “A”, is typically limited to the size of the interacting finger.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy