PCB Technology

How to select high frequency high speed PCB Material

How to select high frequency high speed PCB Material

As microprocessors and signal conversion transmissions increase in speed, digital circuits run at a higher level: 100Gbps. The use of general-purpose PCB boards will not achieve high-speed signal requirements, and the choice of board will determine the performance of the product.

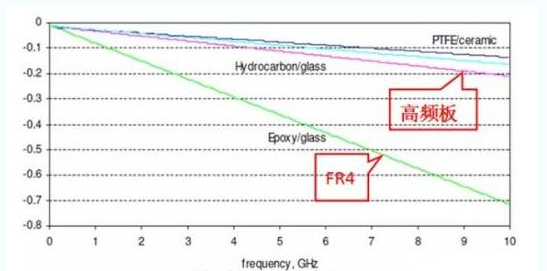

Choosing PCB boards must strike a balance between meeting design requirements, mass production, and cost. Simply put, design requirements include both electrical and structural reliability. This board problem is often more important when designing very high speed PCB boards (greater than GHz). For example, the commonly used FR-4 material, the dielectric loss Df (Dielectricloss) at a few GHz frequency will be large, may not be applicable.

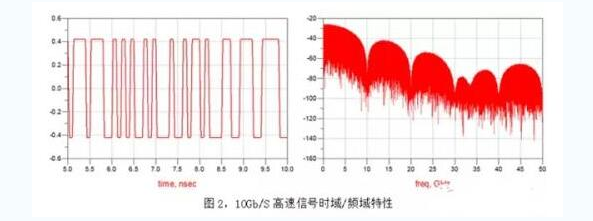

For example, a 10Gb/S high-speed digital signal is a square wave, which can be thought of as a superposition of sinusoidal signals of different frequencies. Therefore, 10Gb/S contains many different frequency signals: 5Ghz fundamental signal, 3rd order 15GHz, 5th order 25GHz, 7th order 35GHz signal, and so on. Maintain the integrity of the digital signal as well as the steepness of the upper and lower edges and the low-loss, low-distortion transmission of RF microwaves (the high-frequency harmonics of the digital signal reach the microwave band). Therefore, in many respects, the requirements for high-speed digital circuit PCB selection and RF microwave circuits are similar.

In the actual engineering operation, the selection of high-frequency plates seems to be simple, but there are still many factors to be considered. Through the introduction of this article, as a PCB design engineer or a high-speed project leader, you have a certain understanding of the characteristics and choice of plates. . Understand the electrical properties, thermal performance, reliability, etc. of the sheet. And rational use of the cascading, design a product with high reliability and good processing, and the consideration of various factors is optimized.

The main considerations for choosing the right board are as follows:

1, manufacturability:

For example, how many press-fitting properties, temperature performance, etc., CAF/heat resistance and mechanical toughness (stickiness) (good reliability), fire rating;

2. Various properties matching the product (electricity, performance stability, etc.):

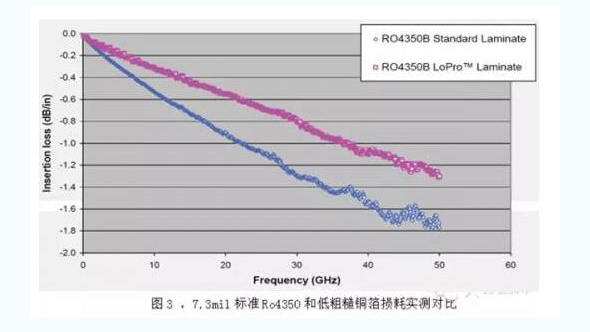

Low loss, stable Dk/Df parameters, low dispersion, small variation coefficient with frequency and environment, small tolerance of material thickness and glue content (good impedance control), if the trace is long, consider low roughness copper foil. In addition, the high-speed circuit needs to be simulated in the early stage of design, and the simulation result is the reference standard of the design. "Xingsen Technology-Agilent (High Speed/RF) Joint Lab" solves the performance problems of inconsistent simulation results and tests. It has done a lot of simulation and actual test closed-loop verification, and the simulation can be consistent with the actual measurement through unique methods.

3. The availability of materials in a timely manner:

Many high-frequency board procurement cycles are very long, even 2-3 months; in addition to the conventional high-frequency board RO4350 in stock, many high-frequency boards need to be provided by customers. Therefore, high-frequency plates need to communicate with manufacturers in advance, and prepare materials as soon as possible;

4. Cost factor Cost:

Look at the price sensitivity of products, whether it is consumer products, or applications in communications, medical, industrial, military;

5. Applicability of laws and regulations, etc.:

To be integrated with environmental regulations in different countries to meet RoHS and halogen-free requirements.

Among the above factors, the running speed of high-speed digital circuits is the main factor for PCB selection. The higher the speed of the circuit, the smaller the selected PCBDf value should be. Medium and low loss circuit boards will be suitable for 10Gb/S digital circuits; lower loss boards will be suitable for 25Gb/s digital circuits; ultra low loss boards will accommodate faster high speed digital circuits at 50Gb /s or higher.

Material Df:

Df is between 0.01 and 0.005 circuit boards suitable for upper limit 10Gb/S digital circuits;

Df is between 0.005 and 0.003 circuit boards suitable for upper limit 25Gb/S digital circuits;

Circuit boards with Df no more than 0.0015 are suitable for 50Gb/S or even higher speed digital circuits.

Commonly used high speed sheets have:

1)Rogers: RO4003, RO3003, RO4350, RO5880, etc.

2)Taiwan Yao TUC: Tuc862,872SLK, Tu787, etc.

3)Panasonic: Megtron4, Megtron6, etc.

4)Isola: FR408HR, IS420, IS680, etc.

5)Nelco: N4000-13, N4000-13EPSI, etc.

6)Dongguan Shengyi, Taizhou Wangling, Taixing microwave, etc.

Of course, there are many other high-frequency panels, such as Arlon (acquired by Rogers last year) and Taconic, which are old-fashioned RF microwave board factories with guaranteed performance.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy