Microwave RF PCB

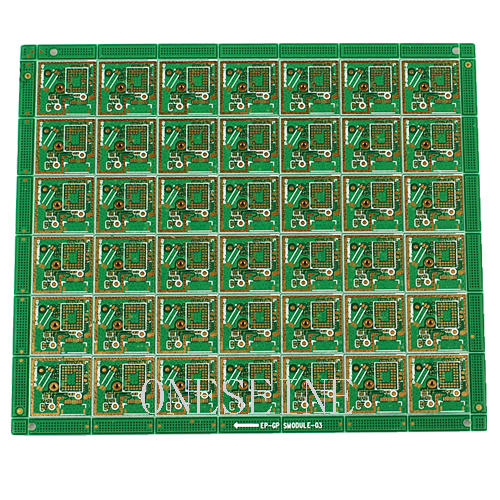

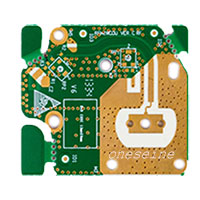

Rogers 4350 5.8G Sensor PCB Rigid Radar Circuit Board Fabrication Service

- Rogers 4350

- 5.8G

- Sensor PCB

- Radar Circuit Board

- Product description: 5.8GHZ Sensor PCB 24GHZ Sensor PCB

Rogers 4350 5.8G Sensor PCB Rigid Radar Circuit Board Fabrication Service

Quick Details

Place of Origin:Shenzhen, China (Mainland)

Base Material:RO4350B

Copper Thickness:0.5oz - 2.0oz

Board Thickness:0.4mm - 5.0mm

Min. Hole Size:6mil

Min. Line Width:3mil

Min. Line Spacing:3mil

Surface Finishing:ENIG, Immersion silver, Immersion tin, OSP

PP:Rogers 4450F, Domestic-(25FR), Domestic-(RF-27), Domestic-(6700)

Solder Mask Color:Green, White, Blue, Black, Red, Yellow

Silkscreen Color:White, Black, Yellow

Introduction:

High frequency board usually use FR4 glass fiber lamination, but also the whole of the epoxy glass cloth repression, more uniform color the entire pcb board, bright. Density larger than the low frequency pcb board

High-frequency electronic devices is the development trend, especially in the growing wireless networks, satellite communications, and information products to high speed and high-frequency, and voice communications products to large capacity and fast transmission of wireless, video, and data normalization.

Therefore, the development of next-generation products require high frequency board, satellite systems, mobile phone base stations and other communications products received must be applied to high-frequency circuit boards, and the inevitable rapid development in the coming years, will be a large demand for high-frequency board.

Material:

(1) The dielectric constant (Dk) must be small and very stable, usually the smaller the better signal transfer rate

(2) The dielectric loss (Df) must be small, which mainly affects the quality of signal transmission, the smaller dielectric loss the smaller signal loss

(3) Consistent with the thermal expansion coefficient of copper

(4) Low water absorption, high water absorption will affect the dielectric constant and dielectric loss at the time of moisture.

(5) Other heat resistance, chemical resistance, impact strength, peel strength, etc. must also be good.

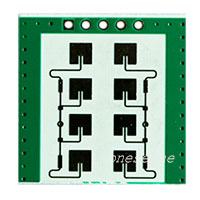

Induction/sensor lamp is using imported technology and MCU circuit design, active infrared work type, have good stability, strong anti-interference characteristics, with infrared decoding, widely used in high demanding commercial and industrial applications. It is a new generation of green energy-saving lighting.

With induction control switch lights, needn't to manually operate, for example, voice control, light control, temperature control, etc. all belong to the induction lamp

Use launch&receive active infrared technology, integrated codec launch, decodes received control output, making powerful with 8-bit microcontroller, using industrial level chip, load capacity, strong anti-jamming capability, suitable for any place.It can turn on lighting automatically ,and delay off automatically after people leave, eliminate human waste of energy, and extend the service life of electrical energy, convenient security in one of the function.

It is actually an automatic switching control circuit

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy