Rogers PCB

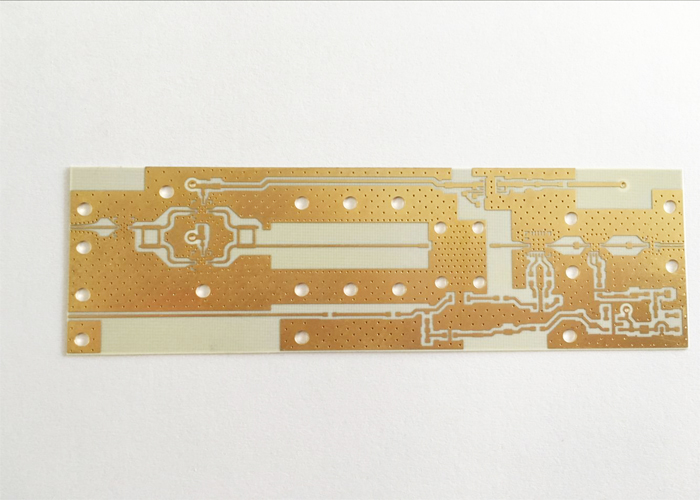

Rogers Laminated Datasheet 4003C 0.2mm Thickness PCB Boards With Immersion Gold Finish

- 0.2mm

- 4003C

- Immersion gold 1U tk

- Rogers Laminatd

- Product description: rogers pcb manufacturers rogers pcb material properties rogers 5880 rogers ro rogers 4450 rogers ro4350 lopro rogers connecticut rogers low loss material

Rogers Laminated Datasheet 4003C 0.2mm PCB Boards With Immersion Gold Finish

Technology:

|

PCB Material: |

Rogers 4003C |

Product Name: |

Rogers 4003 PCB Boards |

|

Layers: |

2 Layer |

Copper |

1oz |

|

PCB Thickness: |

0.25mm |

Surface |

Immersion gold 1U tk |

|

Min. Line Width: |

0.1mm(4mil) |

Min. Line Spacing: |

0.1mm(4mil) |

|

Min. Hole Size: |

0.15mm(6mil) |

Rogers PCB: |

Rogers 4003C pcb |

|

Soldermask |

No |

Silkscreen |

No |

ONESEINE Technology Co., Ltd., established in 2013, is a professional enterprise specializing in flexible circuit boards, PCBs, PCB Assembly, and rigid-flex PCBs. As a high-precision, high-quality comprehensive manufacturer, our products are widely used in mobile communications, smart home systems, optoelectronics, industrial controls, medical equipment, automotive electronics, and consumer electronics.

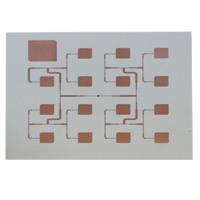

Rogers 4003C material selection:

Generally,4003 0.2MM/0.5MM/0.8MM are sufficient in our company,and the price will be cheaper than other thickness, the cheapest is 0.5MM thickness

For multilayer pcb boards,if you want to save costing and achieve the desired effect,I will suggest you use RO4003 material mix stack up Fr4 material,the main signal layer use rogers 4003 material and the other layer use fr4 material.

You can make some samples pcb prototype and test if it is OK

We have many many customers,their engineers design rogers +fr4 together, and have perfect result,the costing twice cheaper than rogers+rogers

And for single layer rogers 4003 PCB,if you think rogers 4003 exceed your budget, I think you can try to use china-made HIGH FREQUENCY PCB material.F4B high frequency material,the DK have from 2.2-10,DF you can see here,if haven’t,can contact me directly.

Rogers 4003C application:

Automotive, Backplanes, RF / Microwave, High End

Computing

Signal Integrity, Medical, Military, Mobile

Devices / Wireless Handsets

Railway, Servers, Switches/Routers, Thermal

Management, Wireless Infrastructure

Rogers High

Frequency 4003 Material Laminate in stock

Rogers pcb material in stock:

Rogers4003C: thickness(0.2, 0.508,0.813,1.524)

DK 3.38

Rogers4350B: thickness(0.168,0.254 0.508,0.762,1.524)

DK 3.5

Rogers5880: thickness(0.254 ,0.508,0.762) DK 2.2

Rogers3003: thickness(0.127,0.508,0.762,1.524)

DK 3

Rogers3010: thickness(0.635) DK 10.2

Rogers3206: thickness(0.635) DK 10.2

Rogers3035: thickness(0.508) DK 3.5

Rogers6010: thickness(0.635,1.27) DK 10.2

Materials used for HF circuit boards

Based on a

variety of parameters, HF signals are reflected on circuit board, meaning that

the impedance (dynamic resistance) varies with respect towards the sending

component. To prevent such capacitive effects, all parameters must be exactly specified,

and implemented with the highest amount of approach manage.

Vital for the impedances in high frequency

printed circuit boards are principally the conductor trace geometry, the layer

buildup, along with the dielectric continuous (er) on the supplies applied.

For many applications, it is sufficient to use

Rogersmaterial with an appropriate layer buildup. In addition, we process

high-frequency materials with improved dielectric properties. These have a very

low loss factor, a low dielectric constant, and are primarily temperature and

frequency independent.

Additional favourable properties are high glass

transition temperature, an excellent thermal durability, and very low

hydrophilic rate.

We use (among others) Rogers or PTFE materials

(for example, Teflon from DuPont) for impedance controlled high frequency

circuit boards. Sandwich buildups for material combinations are also possible.

The increasing complexity of electronic

components and switches continually requires faster signal flow rates, and thus

higher transmission frequencies. Because of short pulse rise times in

electronic components, it has also become necessary for high frequency (HF)

technology to view conductor widths as an electronic component.

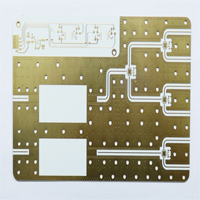

Rogers 4003C 0.2mm Ultra-Thin Boards with Immersion Gold

Demanding high-frequency applications require uncompromising materials and precision engineering. In the world of RF, microwave, and high-speed digital circuits, the choice of printed circuit board (PCB) substrate isn't just important – it's critical to performance, signal integrity, and reliability. Enter the Rogers 4003C Laminated Datasheet material, now available in an ultra-thin 0.2mm thickness and finished with high-performance Immersion Gold (ENIG).

Why Rogers 4003C Matters:

Rogers Corporation is synonymous with excellence in high-frequency circuit materials. The 4003C laminate is a workhorse for engineers demanding:

Exceptional Electrical Stability: Low and stable dielectric constant (Dk ≈ 3.38 @ 10 GHz) and dissipation factor (Df ≈ 0.0027 @ 10 GHz) ensure minimal signal loss and consistent performance across frequency bands.

Superior Thermal Management: Excellent thermal conductivity helps dissipate heat efficiently, crucial for power amplifiers and dense designs.

Low Z-Axis CTE: Minimizes via failure risk during thermal cycling, enhancing long-term reliability.

Hydrocarbon Ceramic Reinforcement: Provides excellent mechanical stability and dimensional consistency for precise impedance control.

The Power of 0.2mm Thickness:

Moving to a 0.2mm (8 mil) Rogers 4003C core offers significant advantages:

Miniaturization: Enables thinner, lighter, and more compact designs for space-constrained applications like aerospace, wearables, and advanced sensors.

Enhanced Flexibility (for Multilayer): Thinner cores are essential for building highly reliable multilayer boards, improving layer-to-layer registration and reducing overall stack height.

Improved High-Frequency Performance: Thinner dielectrics can be beneficial for controlled impedance lines at very high frequencies and for specific coupling requirements.

Rigid-Flex Applications: Ideal as the thin rigid component within complex rigid-flex assemblies.

Immersion Gold (ENIG): The Surface Finish of Choice

Pairing Rogers 4003C with Immersion Gold finish provides the perfect surface for demanding electronics:

Superior Flatness: Essential for reliable soldering of fine-pitch components (BGAs, QFNs, CSPs) and wire bonding.

Excellent Oxidation Resistance: The inert gold surface protects underlying copper from corrosion during storage and assembly, ensuring solderability.

Long Shelf Life: Boards maintain their solderability for extended periods compared to finishes like OSP.

Compatibility: Works flawlessly with both leaded and lead-free (RoHS) soldering processes.

Reliable Contact Surfaces: Provides a durable, low-resistance surface for switches, test points, and connectors.

Applications Demanding Rogers 4003C 0.2mm + Immersion Gold:

This combination excels where performance, precision, and reliability are non-negotiable:

Automotive Radar Systems (77 GHz): Enabling next-gen ADAS safety features.

5G Infrastructure (mmWave): Powering base stations and small cells.

Satellite Communications (SATCOM): Ensuring signal integrity in harsh environments.

High-Speed Digital Design (Backplanes, SerDes): Minimizing signal loss and jitter.

Aerospace & Defense Avionics: Meeting stringent performance and reliability standards.

Medical Imaging & Diagnostics: Demanding accuracy and signal purity.

Engineer with Confidence

Choosing Rogers 4003C in a 0.2mm thickness with Immersion Gold finish means selecting a substrate engineered for success in the most challenging high-frequency environments. You get the proven electrical performance of Rogers' flagship material, the design freedom of ultra-thin cores, and the assembly reliability of a premium surface finish.

Ready to push the boundaries of your next RF or high-speed design?

Download the Rogers 4003C Datasheet & Request a Quote for 0.2mm Immersion Gold Boards Today! [Link to Datasheet] [Link to Quote Request]

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy