Multilayer PCB

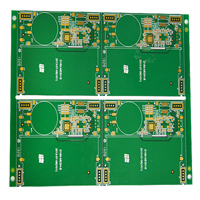

8 Layer Multilayer HDI PCB With Blind Vias Printed Circuit Boards Prototype

- multilayer pcb

- 8 layer pcb

- HDI PCB

- Blind Vias PCB

- Product description: 8 Layer Multilayer HDI PCB With Blind Vias Printed Circuit Boards Prototype

8 Layer Multilayer HDI PCB With Blind Vias printed circuit boards Prototype

General information:

Layer:8

Material:FR4

Thickness: 2.0MM

Surface finish: ENIG

Special: Blind hole,L1-L2,L3-L4,L5-L6,vias filled and capped

Board size:2*6CM

Solder mask:No

Silk screen: White

Name: Multilayer 8Layer Blind Vias PCB Boards

Delivery time: 10days for sample and small&medium batch

About quote:For the special of blind vias pcb,so the accurate quotation have to provide the gerber file(DXP etc.)

Package Details: inner packing:vacuum packing/plastic bag outer packing:standard carton packing

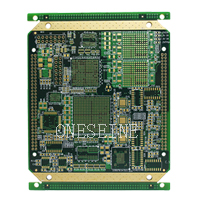

Blind vias:

Blind

vias are used

to connect one outer layer with at least one inner layer.

The holes for each connection level must be defined as a

separate drill file.

The ratio of hole depth to drill diameter (aspect ratio) must be ≤ 1.

The smallest hole determines the depth and thus the max. distance between the

outer layer and the corresponding inner layers.

For detail blind&buried vias pcb

Key words: Microvia, Via-in-Pad

HDI Blind vias PCB:

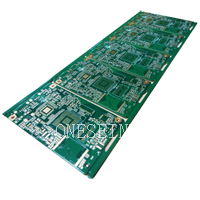

HDI boards, one of the fastest growing technologies in PCBs, HDI Boards contain blind and/or buried vias and often contain microvias of .006 or less in diameter. They have a higher circuitry density than traditional circuit boards.

There are 6 different types of HDI boards, through vias from surface to surface, with buried vias and through vias, two or more HDI layer with through vias, passive substrate with no electrical connection, coreless construction using layer pairs and alternate constructions of coreless constructions using layer pairs.

Special technologies used with HDI any-layer printed circuit boards:

Edge plating for shielding and ground connection

Minimum track width and spacing in mass production around 40μm

Stacked microvias (plated copper or filled with conductive paste)

Cavities, countersunk holes or depth milling

Solder resist in black, blue, green, etc.

Low-halogen material in standard and high Tg range

Low-DK Material for Mobile Devices

All recognised printed circuit board industry surfaces available

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy