Rogers PCB

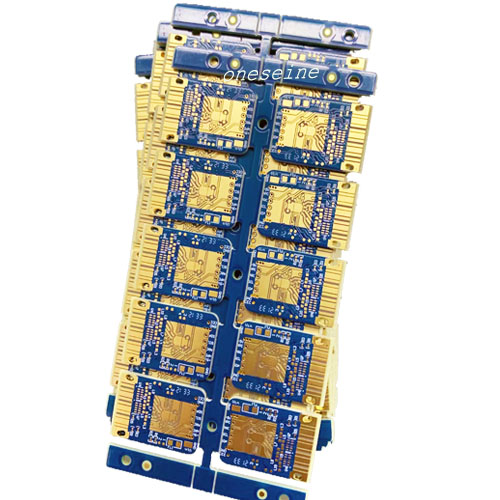

China Cicuit Board Factory Rogers 6035htc PCB Material Fabrication

- rogers circuit board

- rogers dielectric materials

- duroid pcb

- rogers pcb board

- Product description: rogers pcb material dielectric constant 4350b rogers duroid 6010 duroid pcb fr4 rogers mid loss pcb pcb rogers material r04350b ro3003g2 ro4003c dielectric constant ro4003c price ro4350b di

China Cicuit Board Factory Rogers 6035htc PCB Material Fabrication

PCB parameter:

Boards size:12*3CM

Surface finish:ENIG

Boards thickness:0.7mm

Layer:2

Solder mask:Blue

Silkscreen:White

Brand:ONESEINE

Here is some information on Rogers PCB (printed circuit boards)

Rogers Corporation is a leading manufacturer of high-performance circuit materials and components for wireless infrastructure, automotive, aerospace and defense, and other high-reliability electronic applications. Some key points about Rogers PCBs:

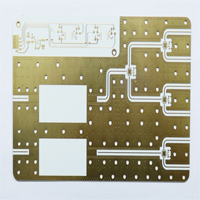

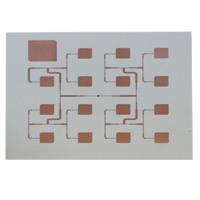

- Rogers produces a variety of high-frequency, high-performance circuit board materials, including PTFE-based laminates, ceramic-filled hydrocarbon laminates, and liquid crystal polymer laminates.

- These materials are designed to provide excellent electrical, thermal, and mechanical properties for demanding RF, microwave, and millimeter-wave applications.

- Rogers PCBs are commonly used in 5G wireless infrastructure, radar systems, satellite communications, and other high-frequency circuit designs.

- The company's product lines include RO4000 Series, RO3000 Series, RT/duroid Series, and other specialized materials optimized for different operating frequencies, thermal requirements, and manufacturing processes.

- Rogers PCBs are known for their low loss tangent, controlled impedance, and thermal management capabilities - key factors for high-speed, high-frequency circuit performance.

- In addition to the circuit board materials, Rogers also manufactures integrated components like circuit protection devices and integrated passive devices using their specialized PCB technologies.

What are the key advantages of Rogers PCBs compared to other circuit board materials?

There are several key advantages that Rogers PCBs offer compared to other circuit board materials:

1. Exceptional Electrical Performance:

- Rogers' PTFE-based and ceramic-filled laminates have very low dielectric constant and loss tangent, enabling low signal loss and excellent high-frequency performance.

- This makes them well-suited for high-speed digital, RF, and microwave applications where signal integrity is critical.

2. Thermal Management:

- Rogers materials have high thermal conductivity, allowing for better heat dissipation and thermal management in high-power circuits.

- This helps maintain signal integrity and reliability of components in demanding operating environments.

3. Mechanical Reliability:

- Rogers laminates offer superior mechanical properties like high flexural strength and low z-axis coefficient of thermal expansion.

- This improves the long-term structural integrity and reliability of the PCB, especially in applications with thermal cycling or mechanical stresses.

4. Design Flexibility:

- Rogers provides a wide range of circuit board materials optimized for different frequencies, layer counts, and manufacturing processes.

- This allows designers to select the most appropriate material for their specific application requirements.

5. Controlled Impedance:

- Rogers' tight control of dielectric constant and thickness enables precise impedance matching, important for high-speed digital and RF circuits.

6. High-Frequency Performance:

- The low loss characteristics of Rogers materials make them well-suited for applications up to millimeter-wave frequencies.

In summary, the key advantages are superior electrical, thermal, and mechanical properties that allow Rogers PCBs to excel in high-frequency, high-power, and reliability-critical applications compared to standard FR-4 or other circuit board materials. This makes them a preferred choice for many aerospace, defense, and wireless infrastructure designs.

How do the thermal properties of Rogers PCBs compare to other materials in high-power applications?

The thermal properties of Rogers PCBs are a key advantage, especially in high-power applications. Let's take a closer look:

1. Thermal Conductivity:

- Rogers materials like RO4000 and RT/duroid series have thermal conductivity values ranging from 0.5 to 2.1 W/m-K.

- This is significantly higher than standard FR-4 PCB materials, which typically have thermal conductivity around 0.3 W/m-K.

- The higher thermal conductivity allows Rogers PCBs to more efficiently dissipate heat, critical for handling high power loads.

2. Coefficient of Thermal Expansion (CTE):

- Rogers laminates have a much lower CTE compared to FR-4, especially in the z-axis (thickness) direction.

- This better matches the CTE of components mounted on the PCB, reducing thermal mismatch and improving reliability.

- The controlled CTE also enables stacking multiple Rogers layers without creating excessive warpage.

3. Operating Temperature Range:

- Rogers materials can operate reliably at much higher temperatures compared to FR-4.

- RO4000 series can handle continuous operation up to 150°C, while RT/duroid can go up to 250°C.

- This extended temperature range is crucial for high-power, high-heat applications.

4. Thermal Management:

- The combination of high thermal conductivity and low CTE allows Rogers PCBs to effectively transfer heat from hot components to cooling structures.

- This enables the use of efficient heatsinks, cold plates, and other thermal management techniques.

5. Reliability:

- The superior thermal properties of Rogers materials translate to higher reliability under thermal cycling and high-temperature operating conditions.

- This is especially important for applications like radar, 5G infrastructure, and aerospace electronics that experience severe thermal stresses.

In summary, the thermal advantages of Rogers PCBs, including high conductivity, low CTE, and wide temperature range, make them ideal for high-power, high-heat applications where effective thermal management is crucial for performance and reliability. This is a key differentiation from standard FR-4 circuit board materials.

Let me provide some more details on the key advantages of Rogers PCBs:

1. Electrical Performance:

- Rogers' PTFE-based and ceramic-filled laminates have exceptionally low dielectric constant (εr) and loss tangent (tan δ).

- For example, the RO4000 series has an εr of 3.55-3.66 and tan δ of 0.0037 at 10 GHz.

- This enables low signal loss, high-speed operation, and excellent high-frequency performance up to millimeter-wave frequencies.

- The tight control of electrical properties also allows for precision impedance matching.

2. Thermal Management:

- As mentioned earlier, Rogers materials have much higher thermal conductivity compared to FR-4, typically 0.5 to 2.1 W/m-K.

- This allows efficient heat dissipation from hot components and better thermal management.

- The low z-axis CTE also minimizes thermal mismatch with components.

- Rogers PCBs can operate reliably at temperatures up to 250°C, far exceeding the limits of FR-4.

3. Mechanical Reliability:

- Rogers laminates have superior mechanical properties like high flexural strength, tensile strength, and peel strength.

- This improves the structural integrity and resistance to failure under mechanical stress or vibration.

- The low z-axis CTE also reduces board warpage during thermal cycling.

4. Design Flexibility:

- Rogers offers a wide range of circuit board materials, including PTFE-based, ceramic-filled, and liquid crystal polymer (LCP) laminates.

- This allows designers to select the optimal material for their specific application requirements in terms of frequency, power, layer count, and manufacturing process.

5. Specialty Applications:

- Rogers materials are widely used in high-frequency, high-power applications like 5G infrastructure, radar, satellite communications, and automotive radar.

- Their superior electrical, thermal, and mechanical properties make them well-suited for these demanding applications.

6. Sustainability:

- Rogers has developed environmentally friendly manufacturing processes and materials to meet increasing sustainability requirements.

- This includes lead-free, halogen-free, and RoHS-compliant PCB solutions.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy