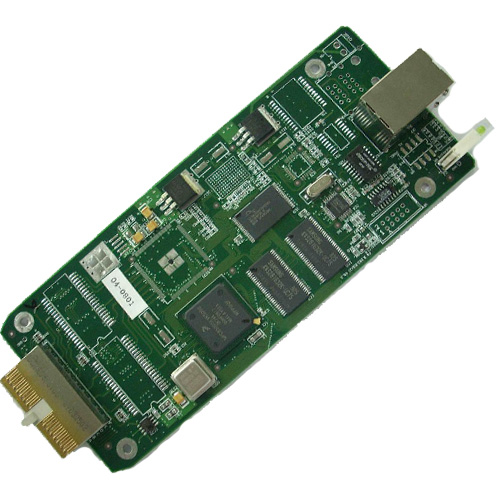

PCB Assembly

PCBA Turnkey Service of PCB Board SMD SMT Assembly

- pcba

- pcb assembly

- SMD

- SMT

- Product description: PCBA Turnkey Service of PCB Board SMD SMT Assembly

PCBA Turnkey Service of PCB Board SMD SMT Assembly

Quick detail:

Mode of production:SMT & DIP

PCB customized:yes

Material:Fr4

Layer:2

Surface finish:HASL lead free

Board thickness:1.6mm

Solder mask:Green

Silkscreen:White

Name:PCBA turnkey service

PCBA turnkey service manufacturer:

PCBA PCB Assembly

- Quality garanteed

- Flexible production

- AOI and visual inspection

- On time delivery

Prototype PCB assembly manufacturing, quick turnkey samples delivery.

- Full turnkey service: Circuit design, PCB layout, PCB fabrication(manufacture), components procurement, PCB assembly, prototype, in-circuit testing, casing assembly, box-build assembly, packing manufacturing.

- Our PCBA manufacturing experience in manufacturing various modes of analog and digital circuit, including middle or small dimension of LCD display technology, IR, supersonic, audio and screen signal processing, LED power supply, lighting controller for various industrial products.

- PCB &PCBA &PCB Assembly &EMS

We offer quotation for clients within 2 hours, and reply E-mail within 3 hours.

More and more of our existing PCB customers are now asking us for fully Assembled printed circuit boards delivered to their door to take away all the time consuming stress of component procurement and assembly. In order to meet customers' requirements, Oneseine develops from a PCB manufacturer to a one-stop PCBA service provider, including PCB assembly, components sourcing, stencils, cable assembly and final product assembly and testing.

|

Available

Services |

Assembly

Technologces |

Our PCBA Turnkey Service advantages :

1) High-end, Small volume and Various kinds of PCBA service offered;

2) Speedy, Flexible and one-stop service in PCBA;

3) Assembly and Purchasing service offered, all components are promised to be purchased 100% from Original factories or their pointed agents;

4) Transparent quotation,cost and benefit are detailedly opened to customer;

5) With professional Engineers and Long-term successful experience in cooperating with

customers inland and overseas, all new projects can be developed faster and better than expected;

6) With USA or Japan imported tin cream and tin bar, and 100% AOI testing during production, all PCBAs we made are more reliable.

What we need:

* Gerber files of the bare PCB

* Bill of materials to include: Manufacturer's part number, type of part, type of packaging,

component locations listed by reference designators and quantity

* Dimensional specifications for non-standard components

* Assembly drawing, including any change notices

* Final test procedures (if available)

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy