Rogers PCB

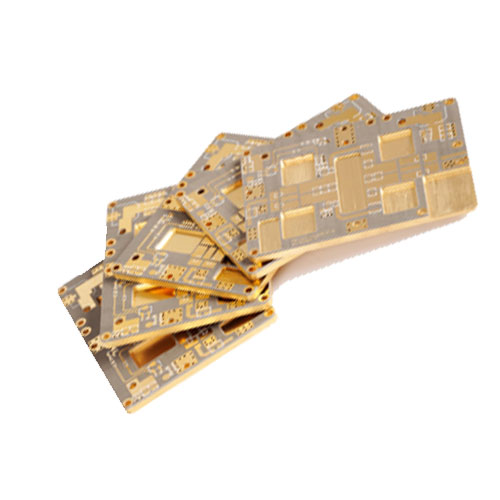

Rogers 3003 0.8mm Thickness Gold Plated High Level Quality PCB Circuit Boards

- rogers pcb

- rogers 3003 pcb

- 0.8mm thickness pcb

- Gold plated pcb

- Product description: Rogers 4003C PCB rogers fr4 pcb stack up pcb Rogers 4360 pcb Rogers Custom PCB Maker Rogers PCB Fabrication rogers pcb price rogers pcb manufacturers rogers pcb prototype rogers pcb calculato

Rogers 3003 Gold Plated High Level Quality PCB Circuit Boards

Quick detail:

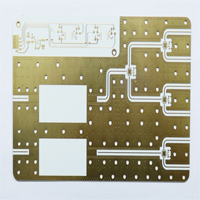

Material:High frequency rogers 3003

Layer:2

Surface finish:Gold plated

Board size:6*3cm

Thickness:0.8mm

Copper weight:0.5OZ

Name:rogers 3003 gold plated high level qulity PCB printed circuit boards

Rogers - High Frequency Circuit Material is glass reinforced hydrocarbon/ceramic laminat ( not PTFE ) designed for performance sensitive, high volume commercial applications

Rogers 3003 PCB:

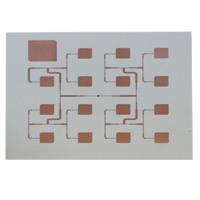

The RO3003 from Rogers Corp. is a ceramic-filled PTFE composite/laminate for use in commercial microwave and RF applications. It features excellent stability with a dielectric constant of 3 up to 40 GHz at room temperature. The material has a dissipation factor (Df) of 0.0013 at 10 GHz and is ideal for band pass filters, microstrip patch antennas, and voltage controlled oscillators.

By far the most commonly used is the Rogers RO4000 series of high frequency materials.

RO4350B laminate is a hydrocarbon/ceramic base, which can be manufactured using

standard FR-4 type multilayer processes, making it not only popular but economical to

manufacture. Low dielectric loss is the major appealing characteristic of this material.

Multilayers can be constructed of a “pure package” using Rogers 4450 prepreg, or by using standard FR-4 prepreg. Popular constructions limit the Rogers material to the “caps” of the stackup thereby managing overall cost by using the material only where it is required, and filling the remainder of the board with standard FR-4 cores/prepreg.

PTFE, commonly known as “Teflon” is another fairly common callout for this genre’s

material requirements. There are many different formulations and laminates such as

Rogers 3000 series ceramic-filled PTFE composites, R/T Duroid 5870 and 5880 glass

microfiber reinforced PTFE, etc. They can be very difficult in multilayer configurations

however, as some require the use of high temperature bonding films or adhesives. The old saying that “nothing likes to stick to Teflon!” sometimes holds true! But their extremely low loss characteristics make them ideal for exacting stripline and microstrip circuit designs.

PCB basic information:

|

Oneseine Technology Go.,LTD |

||

|

Seq |

Item |

capability |

|

1 |

Base Material |

FR-4, High TG FR-4 , Halogen Free material ,CEM-3,CEM-1,PTFE,Rogers ,Arlon ,Taconic,Aluminum base,Teflon,PI ,etc |

|

2 |

Layers |

1-40 ( ≥30 layers needs review ) |

|

3 |

Finished inner/outer copper thickness |

0.5-6OZ |

|

4 |

Finished board thickness |

0.2-7.0mm(≤0.2mm needs review),≤0.4mm for HASL |

|

Board

thickness≤1.0mm: +/-0.1mm |

||

|

5 |

Max panel size |

≤2sidesPCB:

600*1500mm |

|

6 |

Min conductor line width/spacing |

Inner

layers: ≥3/3mil |

|

7 |

Min hole size |

Mechanical

hole: 0.15mm |

|

Drilling

precision: first drilling First drilling:

1mil |

||

|

8 |

Warpage |

Board

thickness≤0.79mm: β≤1.0% |

|

9 |

Controlled Impedance |

+/- 5 % Ω(<50Ω),+/-10%(≥50Ω),≥50Ω+/-5% (needs review) |

|

10 |

Aspect Ratio |

15:01 |

|

11 |

Min welding ring |

4mil |

|

12 |

Min solder mask bridge |

≥0.08mm |

|

13 |

Plugging vias capability |

0.2-0.8mm |

|

14 |

Hole tolerance |

PTH:

+/-3mil |

|

15 |

Outline profile |

Rout/ V-cut/ Bridge/ Stamp hole |

|

16 |

Solder mask color |

Green,yellow,black,blue,red,white,matte green |

|

17 |

Component mark color |

white,yellow,black |

|

18 |

Surface treatment |

OSP:

0.2-0.5um |

|

19 |

E-Test |

Flying probe tester : 0.4-6.0mm,max 19.6*23.5inch |

|

Min spacing from test pad to board edge : 0.5 mm |

||

|

Min conductive resistance : 5 Ω |

||

|

Max insulation resistance : 250 MΩ |

||

|

Max test voltage : 500 V |

||

|

Min test pad diameter : 6 mil |

||

|

Min test pad to pad spacing : 10 mil |

||

|

Max test current : 200 MA |

||

|

20 |

AOI |

Orbotech SK-75 AOI : 0.05-6.0mm,max 23.5*23.5inch |

|

Orbotech Ves machine : 0.05-6.0mm,max 23.5*23.5inch |

||

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy