Printed Circuit Boards

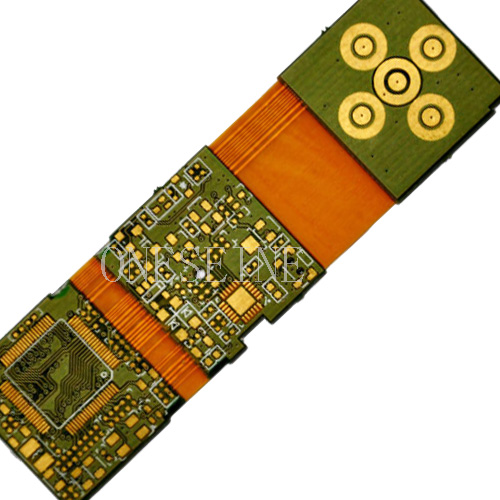

One-Stop OEM Custom Design FPC Rigid Flex PCB

- Polyimide

- Consumer Electronic

- 2 layer

- OEM

- Product description: rigid flex pcb altium rigid pcb definition flex pcb quote cheap flex pcb flex pcb cost estimator flex pcb pcbway rigid flex shaft pcb prototyping services

One-Stop OEM Custom Design FPC Rigid Flex PCB

Quick Details

Place of Origin:Guangdong, China (Mainland)

Brand Name:ONESEINE

Base Material:Polyimide

Copper Thickness:35um

Board Thickness:0.2mm

Min. Hole Size:0.1mm

Min. Line Width:0.1mm

Min. Line Spacing:0.1mm

Surface Finishing:Immersion Gold/HASL

Solder Mask:Green

Silkscreen:White

Test:Test-rig/Flying Probe

Application:Consumer Electronic

Service:Flex Rigid PCB

What is rigid flex PCB?

The birth and development of FPC and PCB gave birth to a new product of rigid flex printed circuit boards. Therefore, the rigid flex printed circuit boards is a flexible circuit board and a rigid circuit board. After the laminating and other processes are performed, the circuit board with the characteristics of the FPC and the characteristics of the PCB is formed in accordance with the relevant process requirements.

Rigid flex printed circuit boards production process editing

Because the rigid flex printed circuit boards is a combination of FPC and PCB, the production of rigid flex printed circuit boards should have both FPC production equipment and PCB production equipment. First of all, the electronic engineer draws the circuit and shape of the rigid flex printed circuit boards according to the requirements, and then sends it to the factory that can produce the rigid flex printed circuit boards. After the CAM engineers process and plan the relevant documents, the FPC production line is arranged. The FPC and PCB production lines are required to produce PCBs. After the two soft boards and hardboards come out, the FPC and the PCB are pressed together by a press machine according to the planning requirements of the electronic engineers. After a series of details, the final system is adopted. Become a rigid flex printed circuit boards. A very important link should be that the hard and soft board is difficult and there are many details. Before the shipment, it is generally necessary to conduct a full inspection because its value is relatively high, so as to avoid the loss of related interests caused by the supply and demand sides.

Rigid flex PCB Advantages and disadvantages:

Advantages: The rigid flex pcb has both the characteristics of the FPC and the characteristics of the PCB. Therefore, it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area. It saves the internal space of the product. , to reduce the volume of finished products and improve product performance is of great help.

Disadvantages: The rigid flex pcb has many production processes, and it is difficult to produce, the yield rate is low, and the materials and manpower are relatively high. Therefore, the price is relatively expensive, and the production cycle is relatively short.

Field of application

The characteristics of the rigid flex pcb determine its application area to cover all the application fields of the FPC in the PCB, such as:

mobile phone

Key board and side keys

Computer and LCD screen

Motherboard and display, etc.

CD Walkman

Drive

NOTEBOOK.

New use

Components such as a suspension circuit (HD) of a hard disk drive and an xe package board.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy