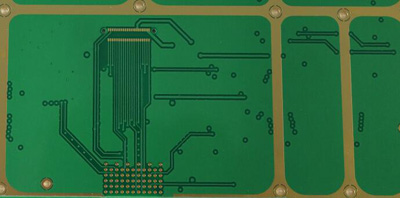

Multilayer PCB

Multilayer Rogers With Fr4 8 Layer Filled Vias PCB Prototype

- filled vias pcb

- via in pad plugging

- copper filled vias pcb

- filled and plated vias

- Product description: filled vias pcb difference between via filling and via plugging kicad filled vias how to fill vias with solder pcb via altium plugged vias pcb planarization via filling with resin via in pad p

Multilayer Rogers With Fr4 8 Layer Filled Vias PCB Prototype

General information:

Material:Rogers3003 5mi Mix stack up FR4 TG170

Layer:8

Board size: 3.2*5cm

Total thickness: 2.2mm

Copper weight: 0.5OZ

Surface finish: Immersion gold

Blind

via Layer 1 to layer 2

Is

an impedance controlled PCB so proof of measured impedance and test coupon to

be supplied

Copper to run to edge

Via filling and over plate ( capped )

Please consult Gerber for full specifications

Filled vias pcb prototype delivery time:6-12 days according to layer number

What’s the difference between resin plug-hole and electroplating hole?

Electroplating hole is vias filled with copper, the hole surface is full of metal,there is no gap, good for welding, but the process requires a high capacity.

Resin plug hole is the hole wall after copper, filled with epoxy resin filled through the hole, and finally the surface of copper, it looks no hole and be good for welding

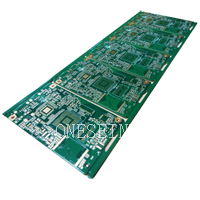

Via Fill. As a refresher, a via is a copper plated hole that is used to connect two or more layers within a PCB together. Via Fill is a special PCB manufacturing technique used to selectively and completely close via holes with epoxy.

What’s the difference between vias cover oil and green solder mask plug hole

Green solder mask plug hole on the whole process is simple, you can solder in the clean room and surface ink together with the operation. The hole will shrink after curing.For customers who require fullness, this way can not meet the product quality.

Vias cover oil is the hole on the ring ring must be covered with ink, emphasizing the hole edge of the ink coverage. Such as false holes exposed copper, red and so on.

Vias filled PCB:

As a refresher, a via is a copper plated hole that is used to connect two or more layers within a PCB together. Via Fill is a special PCB manufacturing technique used to selectively and completely close via holes with epoxy. There are many instances in which a PCB designer might want to have a via filled. Some key benefits are:

More reliable surface mounts

Increased assembly yields

Improved reliability by decreasing the probability of trapped air or liquids.

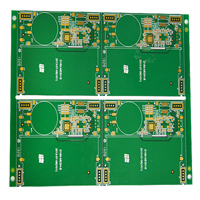

Conductive vs. Non-Conductive Via Fill

Non-Conductive Via Fill, sometimes confused with Via Plug, still has copper plated vias to conduct power and heat. The via, however, is filled with a special low shrinkage epoxy specially formulated for this application. Conductive via fill has silver of copper particles distributed throughout the epoxy to provide extra thermal and electrical conductivity.

Non-Conductive fill has a thermal conductivity of 0.25 W/mK whereas Conductive pastes have a thermal conductivity anywhere from 3.5-15 W/mK. In contrast, electroplated copper has a thermal conductivity of more than 250W/mK.

So while Conductive via fill can offer needed conductivity in some applications more often than not it is possible to use non-conductive paste and add additional vias. Often this results in superior thermal and electrical conductivity with minimal cost impact.

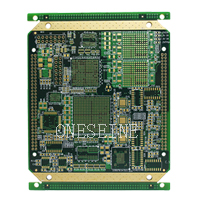

Via Filling with Resin

The vias to be filled are filled with a special hole plugging resin, TAIYO THP-100 DX1 thermally curable permanent hole filling material, using a dedicated machine, ITC THP 30. The extra production steps needed for Resin Via Filling are performed before the 2-layer PCB production process. In case of making multi layers, this is after pressing.

Picture2Overview of the extra processes:

Drilling of only the vias that need filling

Cleaning: plasma and brushing

Black Hole

Apply dry resist

Imaging of ONLY the via holes

Via hole galvanization (PTH)

Strip dry resist

Brushing if needed

Baking: 150°C for 1 hour

Via plugging with resin

Baking: 150°C for 1.5 hours

Brushing

Via Filling with Soldermask

The vias to be filled are filled using soldermask ink as hole-filler substance. This Via Filling technology uses a drilled ALU sheet to push normal soldermask ink in the via holes to the filled. This is a screen-printing process. This is a step before the normal soldermask process.

Important:

The filling is always done from the top side of the board

Vias filled with soldermask always get a reverse soldermask pad added with size via-toolsize+0.10mm.

In other words, this Via Filling type will always be covered with soldermask on top and bottom.

Categories

Latest News

Contact Us

Contact: Ms Tracy

Phone:

Tel:

Add: BludingA,Shixiaganglian Industrial Park,Shajing,Baoan,Shenzhen,China

Tracy

Tracy